I know the Rota-beam line was considered heavy duty and the Deputy/Corporal line was light duty, but what were the actual differences? These descriptions are from the same 1970 pamphlet.

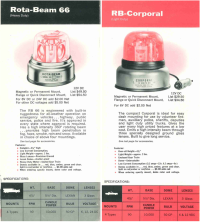

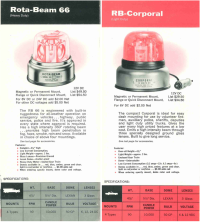

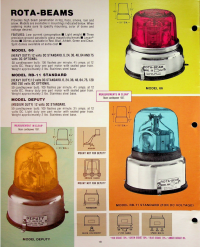

Rota-beam 66 vs. Corporal

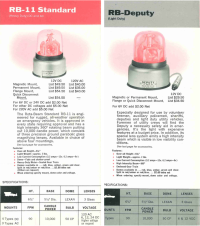

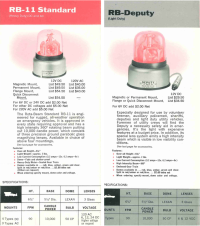

Rota-beam 11 vs. Deputy

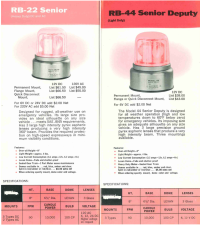

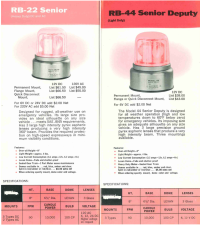

Rota-beam 22 vs. 44 Senior Deputy

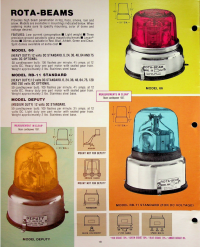

This is the 1976 catalog. The "Senior" 44 and 55 sizes seem to have differing bulb holders. I'm not sure if that's just the picture though.

The "lines" begin to merge in 1980/81. The 44/55 size now houses 80h rotators.

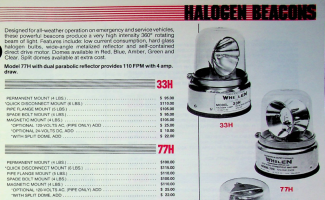

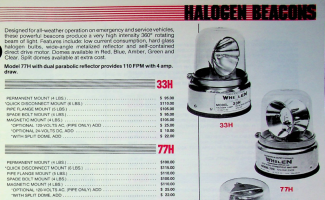

The 1983/83 discontinuation notice for the deputy / corporal line. The 77h is added in the larger size dome.

The motor terms in the 1970 pamphlet don't seem defined, they used "sealed", "enclosed", and "two part" but sealed and enclosed may be being used interchangeably? The biggest differences seem to be in the 66 vs. Corporal, the dome and bulb mounts are very different. The other models seem much more similar, yet still get light and heavy duty labels and price tags to go with them. I know the models evolved over the years, it's interesting how differentiated they were to start.

@dmathieu may have some more insight.....

Rota-beam 66 vs. Corporal

- "Heavy duty" vs. "Light duty" description

- Metal dome ring vs. twist on dome with rubber boot.

- Screws through the doome suspending the bulb vs. internal brackets

- 6, 12, and 24 VDC vs. 6 and 12

- Prices

Rota-beam 11 vs. Deputy

- "Heavy duty" vs. "Light duty" description

- Multiple DC and AC voltages vs. two DC options

- Prices

Rota-beam 22 vs. 44 Senior Deputy

- "Heavy duty" vs. "Light duty" description

- Multiple DC and AC voltages vs. two DC options

- Prices

- Two part motor vs sealed?

This is the 1976 catalog. The "Senior" 44 and 55 sizes seem to have differing bulb holders. I'm not sure if that's just the picture though.

The "lines" begin to merge in 1980/81. The 44/55 size now houses 80h rotators.

The 1983/83 discontinuation notice for the deputy / corporal line. The 77h is added in the larger size dome.

The motor terms in the 1970 pamphlet don't seem defined, they used "sealed", "enclosed", and "two part" but sealed and enclosed may be being used interchangeably? The biggest differences seem to be in the 66 vs. Corporal, the dome and bulb mounts are very different. The other models seem much more similar, yet still get light and heavy duty labels and price tags to go with them. I know the models evolved over the years, it's interesting how differentiated they were to start.

@dmathieu may have some more insight.....

Last edited: