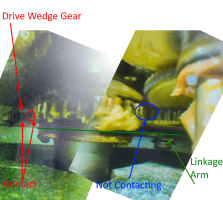

The rota-beam command oscillates 205°, the perfect amount to display 3 of the beacon's 4 bulbs. But how does it oscillate? It seems like the travel is too far for a standard cam / arm mechanism like the 174. I think it reverses motor polarity.

I noticed a few things;

Here is a video of it running

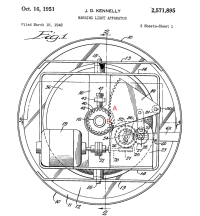

174 mechanism, not at all similar.

And if you are curious about Rowe motor company... well here is what happened to them. Superfund site! https://cumulis.epa.gov/supercpad/SiteProfiles/index.cfm?fuseaction=second.Cleanup&id=0202330

I noticed a few things;

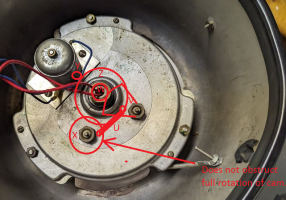

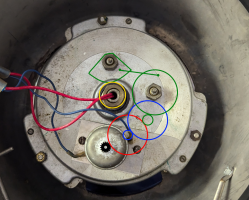

- The motor and light itself have no required polarity. You must ground one wire and then power the other.

- The motor reverses if you reverse the polarity.

- There are two lugs on the bottom that seem to correspond with stop points of oscillation.

Here is a video of it running

174 mechanism, not at all similar.

And if you are curious about Rowe motor company... well here is what happened to them. Superfund site! https://cumulis.epa.gov/supercpad/SiteProfiles/index.cfm?fuseaction=second.Cleanup&id=0202330

Last edited: