C2Installs

Member

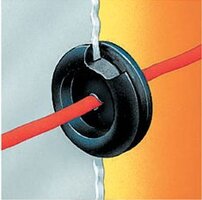

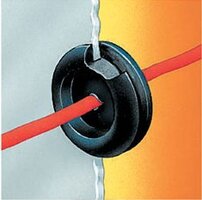

Installing HAWs in headlight housings has become more difficult with newer composite headlight designs. Often the host reflector is contained inside an outer shell. This dual-wall design makes installing HAWs tough and requires the upfitter to drill two holes, one bigger access hole in the outer shell and a 1" mounting hole in the reflector. Since the headlight is a sealed unit, it becomes necessary to "plug" the access hole to keep out moisture and elements. Plugging is done in a variety of ways but most commonly by using the cut-out plastic blank from the hole saw. But, the fit is often off because of the amount of material remove by the hole saw. I have come up with a different method and think it is a better way to roll.

If you are familiar with Jotto Desk laptop mounts then you have seen the round foam adhesive disks that they use to pad the laptop platform. They are a bit less than 1/4" thick and 1 1/2" in diameter with 3M adhesive on the back side. I have a small stock of them on hand because they are useful for a lot of things...like leveling out dashlights for example. I have also found they make an ideal plug for the above described access holes.

The access hole size I prefer to drill is 1 1/2", made with a standard bi-metal hole saw. This is the minimum size needed to just barely allow for the HAW to be inserted due to the size of the HAW's mounting flange. Both screw-in strobe and LED HAWs can be accommodated this way. The access hole saw is used to just start the HAW mount pilot hole, locating it dead center of the access hole. Then I use a 1" step bit to drill out the mounting hole. After cleaning up any debris, I mount the strobe.

To use the foam plug, I make the hole for the wires. For strobe HAWs, I have to make three separate small holes due to the way the wire exit the back of the bulb. I then unpin the AMP connector using a proper tool and feed the wires through the plug, sticky-side towards bulb. For LED units, one hole is fine, but you will need to make a radial cut through to the edge of the foam plug on one side because of the in-line flasher. Once wires are fed, remove the backing paper from the adhesive side and push the foam plug down to the bulb, seating it. The adhesive holds it in place. Depending on how deep your reflector is in relation to the access hole, you may need to stack the foam plugs, sticking them on top of each each other. Finally, seal it all up with RTV silicone and let it set up.

That's it and here are the pics to show you what I mean. This was done on a 2011 GMC Sierra. BTW, the debris clean-up on these sucked in a way few things have sucked before.

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0231.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0233.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0235.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0239.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0240.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0245.jpg

Anyway, give it a shot. I think it works great, looks good, and is easy to do.

If you are familiar with Jotto Desk laptop mounts then you have seen the round foam adhesive disks that they use to pad the laptop platform. They are a bit less than 1/4" thick and 1 1/2" in diameter with 3M adhesive on the back side. I have a small stock of them on hand because they are useful for a lot of things...like leveling out dashlights for example. I have also found they make an ideal plug for the above described access holes.

The access hole size I prefer to drill is 1 1/2", made with a standard bi-metal hole saw. This is the minimum size needed to just barely allow for the HAW to be inserted due to the size of the HAW's mounting flange. Both screw-in strobe and LED HAWs can be accommodated this way. The access hole saw is used to just start the HAW mount pilot hole, locating it dead center of the access hole. Then I use a 1" step bit to drill out the mounting hole. After cleaning up any debris, I mount the strobe.

To use the foam plug, I make the hole for the wires. For strobe HAWs, I have to make three separate small holes due to the way the wire exit the back of the bulb. I then unpin the AMP connector using a proper tool and feed the wires through the plug, sticky-side towards bulb. For LED units, one hole is fine, but you will need to make a radial cut through to the edge of the foam plug on one side because of the in-line flasher. Once wires are fed, remove the backing paper from the adhesive side and push the foam plug down to the bulb, seating it. The adhesive holds it in place. Depending on how deep your reflector is in relation to the access hole, you may need to stack the foam plugs, sticking them on top of each each other. Finally, seal it all up with RTV silicone and let it set up.

That's it and here are the pics to show you what I mean. This was done on a 2011 GMC Sierra. BTW, the debris clean-up on these sucked in a way few things have sucked before.

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0231.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0233.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0235.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0239.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0240.jpg

[Broken External Image]:http://i499.photobucket.com/albums/rr351/C2Installs/IMG_0245.jpg

Anyway, give it a shot. I think it works great, looks good, and is easy to do.