I needed a compact switchbox but could not find exactly what I was looking for. It needed to be very compact and easy to mount on the side of the center console/hump and have LED rocker switches on the bigger side. I found the following at radio shack: a 6X4X2 plastic project box (http://www.radioshack.com/product/index ... Id=2062283) for $5, and these chunky rocker switches (http://www.radioshack.com/product/index ... nSession=1) 4 @ $3. I simply drilled 4, 1/2" holes on the side of the box, and will drill another 1/2" hole in the bottom for the wiring loom to exit. Overall a simple project, looks pretty good, and is very cheap. The box is only going to run 2 pimp pods on 1 switch, a TIR4 6 head on another switch, and a 2 head Axixtech TIR LAW set on another switch. The 4th is a spare for now. In case you were wondering, I used rocker switches that mount into 1/2" holes as I find them much easier to mount.

Step 1- Assemble your gear. You will need a screwdriver with Phillips bit to close the box (not necessarily needed in making box), a drill and a 1/2" drill bit of your choice, your switches, and the box. I prefer to use the wood bit on a fast speed as it melts through plastic with ease and leaves a nice clean hole.

Step 2- Drill your holes. The project box has little lines used to mount things inside and I basically centered the switches inside, really helps keeping everything lined up neatly.

Step 3- Mount your switches, simply screw them in the holes.

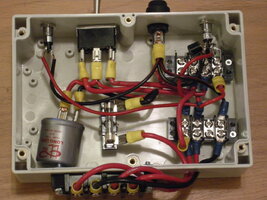

Step 4- All done! Wire it up, mount it and your good to go. As you can see the actual box is smaller then the footprint of a dollar bill. The box has plenty of room inside for the wiring.

Step 1- Assemble your gear. You will need a screwdriver with Phillips bit to close the box (not necessarily needed in making box), a drill and a 1/2" drill bit of your choice, your switches, and the box. I prefer to use the wood bit on a fast speed as it melts through plastic with ease and leaves a nice clean hole.

Step 2- Drill your holes. The project box has little lines used to mount things inside and I basically centered the switches inside, really helps keeping everything lined up neatly.

Step 3- Mount your switches, simply screw them in the holes.

Step 4- All done! Wire it up, mount it and your good to go. As you can see the actual box is smaller then the footprint of a dollar bill. The box has plenty of room inside for the wiring.